At Barcelonesa, we’ve been offering Pickling and Hot Galvanising solutions for more than 20 years. We know that top quality products, backed by an excellent technical advice, are the key to achieve the best metal treatments.

Our service is what distinguishes us from the rest: proper product transport with delivery adapted to suit your needs (in terms of timing and format), fast response to your queries and requirements, and a technical team that will be by your side at all times to help you find the solution that best suited for your manufacturing problems.

Excellent Service

Delivery adapted to your needs, agile time of response, and quality advice.

Verified products

Products verified at European level by numerous manufacturers and distributors.

Technical advice

We have a team that is well-prepared to work alongside you and offer you a customized solution.

Global partner

We offer a wide range of specialities and commodities for all the phases.

Products at all stages

We work with chemicals for the following stages of the stainless steel treatment process.

Services

We also offer you the following services.

Degreasing

Thorough cleaning of the surface to optimize the following stages and to guarantee a perfect finish. Of two types: ACID or ALKALINE. Each option offers specific benefits that have to be taken as an advantage in each installation. The specific products we offer for the degreasing process are:

- BD Galvanet: Acid degreasingagent

Pickling

Steel is pickled to remove impurities, rust, and swarf. However, during this stage, the bare iron is also targeted.

The inhibitor protects the clean metal during the treatment in the pickling bath with hydrochloric and/or sulphuric acid. There is less iron dissolved in the acid, which reduces the acid use and prevents hydrogen fragility. Below you have a list of the solutions we can offer you for the pickling process:

Raw Materials:

Hydrochloric Acid

Sulphuric acid

Phosphoric Acid

Flux

The purpose of the Flux process is to activate the surface of the steel to ensure that the hot zinc is properly deposited and to prevent the formation of unwanted layers of rust that could lead to the incorrect adhesion of the zinc to the metal base. The products we offer for these process include:

- Zinc chloride

- Ammonium Chloride

- Oxygenated water

- Ammonia

Passivation

Passivation is a conversion chemical treatment for recently galvanized steel surfaces. It creates a transparent or barely-visible layer that provides enhanced corrosion resistance to galvanized steel surfaces.

Durante los procesos de decapado, galvanizado en caliente y zincado se genera cloruro ferroso. Este residuo debe ser tratado por empresas especializadas y además puede ser valorizado y reutilizado en otros procesos industriales. Barcelonesa es gestor autorizado de residuos E-1262.11 para realizar la valorización de productos químicos y además somos centro de transferencia. Podemos recoger y gestionar el ácido agotado del galvanizado de sus instalaciones. Contamos con una empresa de transporte propia, autorizada para transportar residuos T-3363.

El proceso de galvanizado en caliente se realiza por inmersión del acero en un crisol con zinc fundido a 450 grados centígrados. En este proceso se forman en la superficie del acero capas de aleaciones de hierro/zinc y una capa gruesa de zinc que permiten una protección contra la corrosión del acero durante muchos años.

Looking for a specific product?

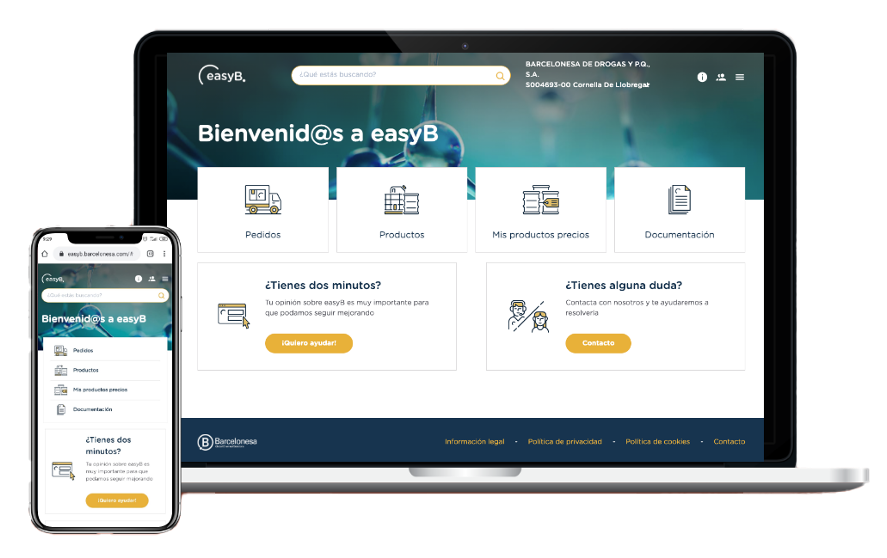

Through our easyB platform, you can see all the products we have available, download documentation and much more.

Quality

Certifications that guarantee that we comply with the highest quality standards in terms of products, services and management.

How can I help you?

Albert García

Sector Manager